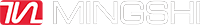

1.1 Preparation of materials and tools

Relevant materials and tools should be prepared according to the construction design requirements, including pipes, fittings, shears, reamers, applicable spanners and other materials required on the construction site.

1.2 Expansion and measurement

Expand the required aluminum-plastic composite pipe (applicable for coiled pipe, not required for straight pipe), and measure the expanded aluminum-plastic composite pipe according to the construction drawings or the actual requirements of the site.

1.3 Pipe cutting

Use pipe shears to cut the measured pipe.

1.4 Reaming

Use a reamer to round the cut multi-layer pipe, and chamfer the inside and outside of the pipe end.

1.5 Fitting check

Before assembling pipes and fittings, check whether each fitting is complete (as shown in Figure 2).

1.6 Assembly

Insert the nuts and brass ring of the matching ferrule joints into the reamed pipe in turn, and smoothly insert the pipe into the sockets of the fitting along the axis, and ensure that the pipe is pressed against the whashers.

1.7 Locking

Move the brass ring against the fitting body , screw on the nut, and use a spanner with a reasonable length to lock it until the brass ring is closed (be careful not to exceed the installation torque to avoid breaking the pipe).

1.8 Connection Diagram

2.Construction and maintenance precautions

a. Multi-layer pipes, fittings must use our supporting products or other brand products approved by our company.

b. Multi-layer pipes and fittings should be stored indoors to avoid rain and direct sunlight.

c. Multi-layer pipes for gas shall be constructed in strict accordance with CECS 264-2009 "Technical Specifications for Construction Gas Multi-layer Pipes - Pipeline Engineering".

d. During construction, should handle with care, do not bump each other, and do not rub against hard objects, to avoid any deformation and damage of pipes and fittings.

e.When expanding the pipe, the pipe should be placed on a soft surface or a flat hard surface, and the pressing force onto the pipe should be moderate to avoid damage to the pipe surface due to hard objects and deformation due to excessive pressing force.

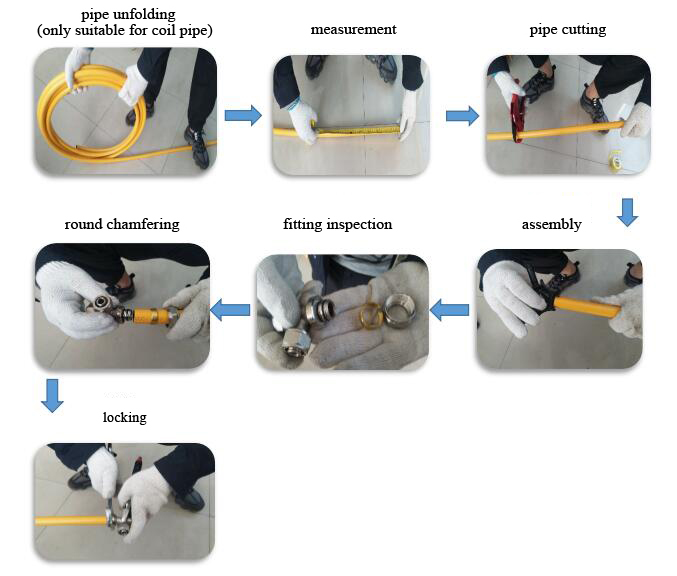

f.When cutting the pipe, the cutting end should be perpendicular to the axis of the pipe, and there should be no obvious inclination, burrs, etc. (as shown in Figure 4)

g.The pipe must be reamed before installation to avoid difficulty in inserting, the sealing ring's out of position, and the sealing ring’s damaged (as shown in Figure 5).

h. During assembly, the insertion of pipes and fittings must be uniformly applied along the axial direction and inserted smoothly to avoid displacement or damage of the seal caused by excessive force.

i. The locking must be in place. Generally, you can see whether the brass ring is closed from the end of the nut, but do not use too much force for locking, and the torque must be limited to the maximum installation torque to prevent the pipe from breaking.

j.After the multi-layer pipes and pipe fittings are scrapped, they should be handed over to the enterprises with relevant qualifications for recycling.